This page details the restoration

of my Karl Griesbaum Singing Bird Cage

A Very Brief History of Singing

Bird Cages

For a couple

of centuries now a few

individuals, their families, and companies have produced mechanical

singing

bird automatons(Sometimes called

Singing Bird Tabatieres). In

the past

these devices were playthings for the rich. Today these are

collectibles and

heirlooms.

In more

recent

times these

mechanical singing birds were the inspiration for the creation of

modern animatronics.

Singing

birds were put into boxes, clocks and in realistic looking displays,

including

cages!

This

page focuses on the German built, Karl Griesbaum

Singing Bird Cage. Production of these stopped in the 1980s but

the designs,tooling and parts were purchased sometime later and

reopened as MMM in

Germany.

I have been

able to determine they are are still making these as of 2016!.

Though I don't have a place for you to buy them in the USA at this

point...

New Info:

The Wendel Family of Rudeheim am Rhein purchased the

Griesbaum factory in the late 1980's. Originally they

intended to place all of the

factory machinery in their museum of mechanical musical instruments.

Instead they decided to use the machinery to continue producing those

things that the Griesbaum factory had in the past, and they continue to

today.

Their museum is located in a 15th century Knights Manor, how cool is

that.

The Museum webpage can be found here www.smmk.de

(tell them steve sent you, if you visit)

Here is the cage I purchased, when it arrived.

Note the dent in the case on the right, the warped bent cage and white

berries.

This photo shows the condition inside the cage a little better. Though

not obvious in theses photos the bird is filthy.

The seller indicated it had sound, but basically there is no sound.

The mechanism seems to function well with the exception of the bird not

singing.....more later.

So, the restoration of this is 2 part.

Repair the physical damages to the cage itself, the bird and it's

props and restore the singing voice to the bird....silenced for how

long?

The following photos show the condition of the inside.

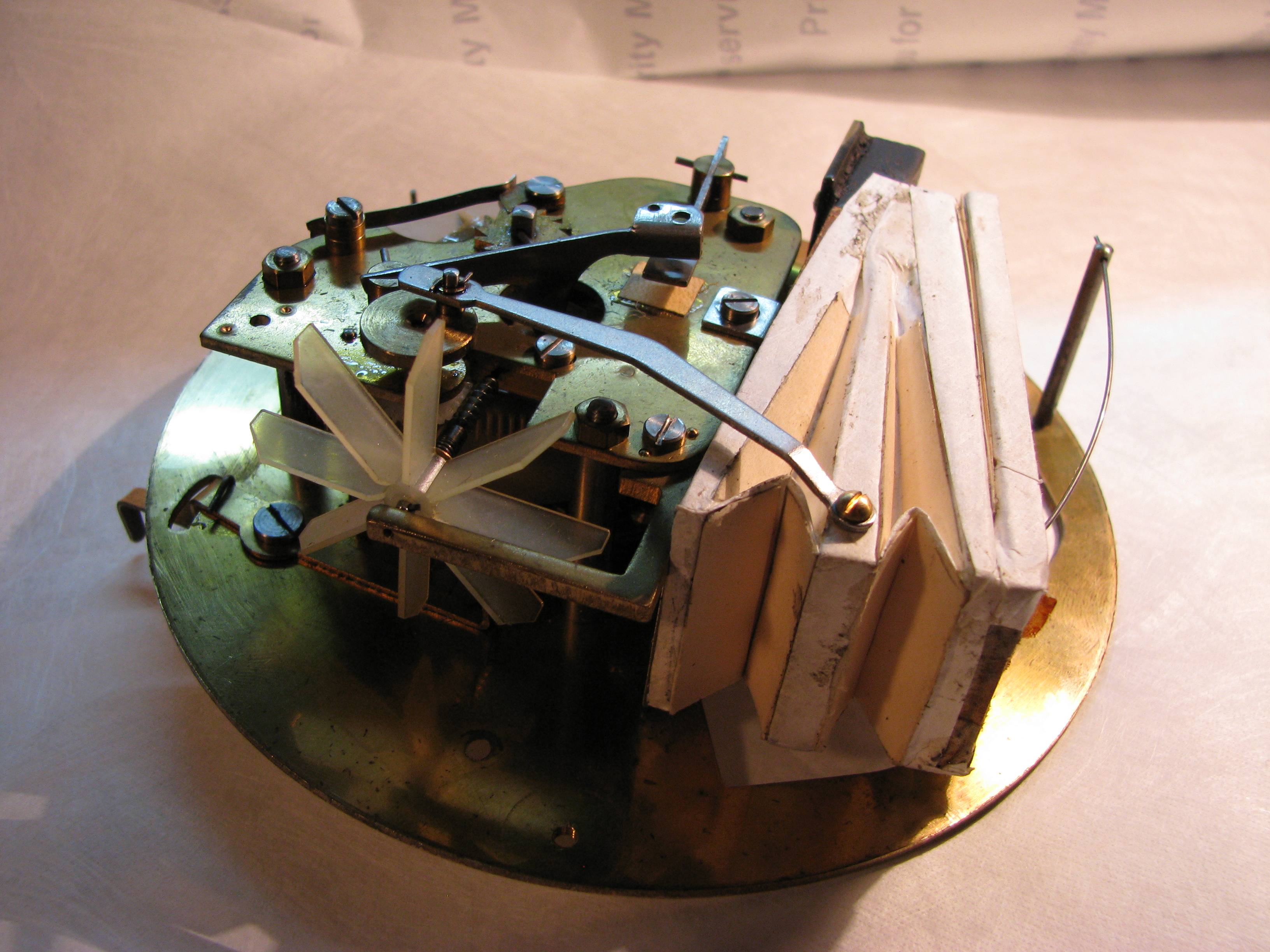

It's clear in this photo that the bellows has been repaired in the past.

The round cylinder on the right is the slide whistle, and what is

ultimately responsible for the birds song.

This assumes that there is enough air supplied to it as well as the

mechanism operating the slide correctly.

The arms located in the center with the small and larger hole operate

the mouth, the head, and the tail of the bird movement.

Since the bellows chamber at the bottom is the reserve and did not move

at all I initially suspected the bellows chamber at the other side as

leaking.

It took a little while for me to realize that one side pumps then the

other of the first 2 chambers.

I looked for replacement material to use as a test.

My research and inquires suggested using animal intestine skin known as

zephyr skin. It was clear this unit did not use such skin.

A video of one of this cages being constructed also did not appear to

show "skin" used.

Since getting a hold of that skin is not all that easy I started to

look for a substitute, at least to test it.

I found someone that suggested the material known as tyvek was a

possible choice.

I eventually found a youtube video where someone used it on a cuckoo

clock whistle with good results.

Tyvek "paper"material is more like cloth material than it is paper as

is paper money.

It's extremely strong, the fibers so tight it does not allow air

through.

It's flexible and can be creased and folded and will accept glues.

Since I had nothing to loose, I decided to give it a shot. Trying a

single section first.

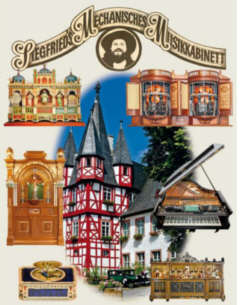

I created a drawing to use as a guide to reproduce the original,

then taped it to the tyvek and cut it out.

Since this was just a test, the worse that could happen was to remove

it, if it didn't work......but it did.

However, now there was some air for the whistle, and some sound, but

not enough. So I

did the next section, and it got better.

It still wasn't right, so I put a little soap in water and using an

artist brush painted it on to the large reserve bellows section....and

guess

what, when pumped

there was small bubbles forming on the material....so it wasn't

airtight after all and it had to go as well..

After removing the reserve bellows material and making a template (this

one is different than the other 2 sections-larger) I was

ready to recover that as well, so...bottom line I should have taken it

all off to start, and replaced all of it.

I also tested the one way valves that are

inserted into sections of the bellows, which as it would imply allow

air to move in one direction only.

I used a piece of tubing sized to fit over the valve. In this way I

could tell if it closed and opened.

I was told that earlier versions of bellows used "paper" valves for

this purpose. A simple flap of paper held at one end that would allow

air in one direction.

A date scratched into the bottom plate interior dates my cage to 1969.

Once all three sections material was replaced the volume of the

whistle increased as well as movement of the reserve section.

It now sounded like what I had imagined it should sound like.

The bird animation control rods go into the 2 holes in the bright metal

arm near the center.

An arm from

the mechanism moves the block of wood in the center

left and right , each section of the bellows pumping air.

As can be seen in

the photos, the bellows has 3 compartments, not seen are very small

round brass & plastic? valves between them. The divider between the

first 2 sections moves and is driven by the mechanism (see arm attached

in photo).first one then the other pumps and fills the final chamber

which has a small slide whistle and release valve attached to it. The

mechanism moves the plunger (piston) of the slide whistle in and out

and opens and closes the air valve to produce the whistled melody. At

the same time the mechanism will rotate the head of the bird, move the

beak, and tail feathers by raising and lowering the arms that cross

near the top of the upper plate.

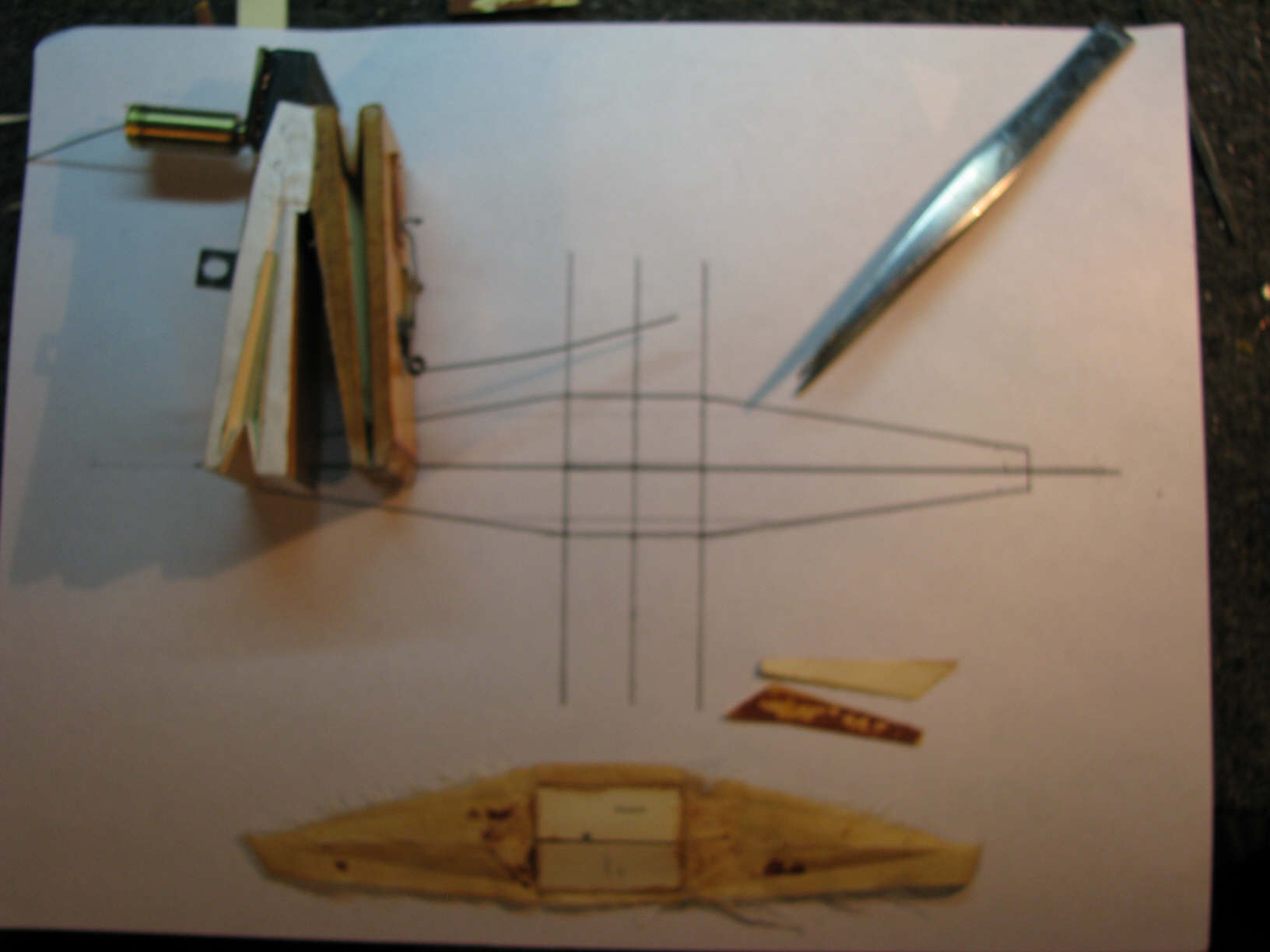

The photo below shows the first pumping section replaced, along with

the drawing used to cut out the new material.

Also shown is one of the original stiffeners, and a replacement.

At the bottom is the actual material found on the bellows.

The folds were put in when the material was installed, then the

stiffeners were added. I used paper from a file folder for the

stiffeners,,

which frankly looked to be exactly the type of paper originally used.

I used the flat back end of a tweezers to help make the folds sharp.

Once I was happy with the folds the stiffeners were glued in place.

This is most likely not the way these coverings were made in the past,

and probably not the way current restorations are done.

I tried this method since I knew I had the time to position the folds

and then add the stiffeners and finally glue them in place.

In production these things would have been put together as a "assembly"

before they were glued to the wood.

Since the material size was accurate, gluing it to the edges of the

wood was all that needed to be done, the folds added and finally

the stiffeners in those folds.

Note: The reserve section had stiffeners added to both sides of the

material as found , I only put them on the outside as I had done with

the other sections.

In this photo all 3 sections have now been replaced.

Next was to deal with the cage , the lower base trim and the interior

space for the bird as well.

The bird was carefully cleaned using an artist brush and water only.

The 2 berries had almost no red paint left on them and it turns

out are made of a material that is water soluble, the one on the right

basically dissolved when cleaned. It appeared that this bird had three

berries, so while created a replacement for the one on the right I

created another for the left side as well (using epoxy). The original

on the left

was savable. Instead of lacquer I used acrylic but covered it

with triple thick clear coat to protect it and give it a gloss finish.

The mushroom red also fell off and was replaced with new white dots

added.

Using an artist brush with a soap solution , each leaf was scrubbed.

Some of the wire connecting the leaves was rusting, in which case

it was painted a brown shade.

Here it's in process, still more cleaning to go.

The feathers on the bird are not perfect but after cleaning it looks a

lot better.

There was one additional repair needed to the bird. The upright post is

normally soldered to the base plate. It had broken free allowing the

bird

mount to turn instead of being fixed in position, which it needs to be

or the alignment of the rods coming from the bird into the mechanism

will bind, which will cause mouth to stay open or closed, stop tail

movement or head turning.

Once I was sure of the position it needed to be in, I re-soldered the

two pieces together.

The bird was then put on the side waiting for final assembly.

Next came working on the base trim, which shows signs it had an impact.

I built a jig for this purpose, simply tracing the curve of a

good area of the base and used a jigsaw to cut it out.

This mimics the shape of the trim. It was placed inside the trim, and

clamps were used to pull the metal back into shape

The cage was also twisted a bit and that was corrected as well.

A final cleaning and it was ready to put it back together.

Final test.

I noticed after I took this photo that the cage bars aren't 100%,

I will go

back and fix that shortly.

You'll notice that the cage doesn't look like the polished brass on the

bass, that is because I've been told

it's plated in gold.

Click here or the above photo for video : Birdcagevideo

With what I learned from the single bird cage I decided to tackle

a 2

bird cage.

Here it is as purchased.

Overall it is in nice physical condition, the cage a little

bent. The base is a very nice

design, again with a few issues.

The big issue, it doesn't do anything, It does not operate

at all.

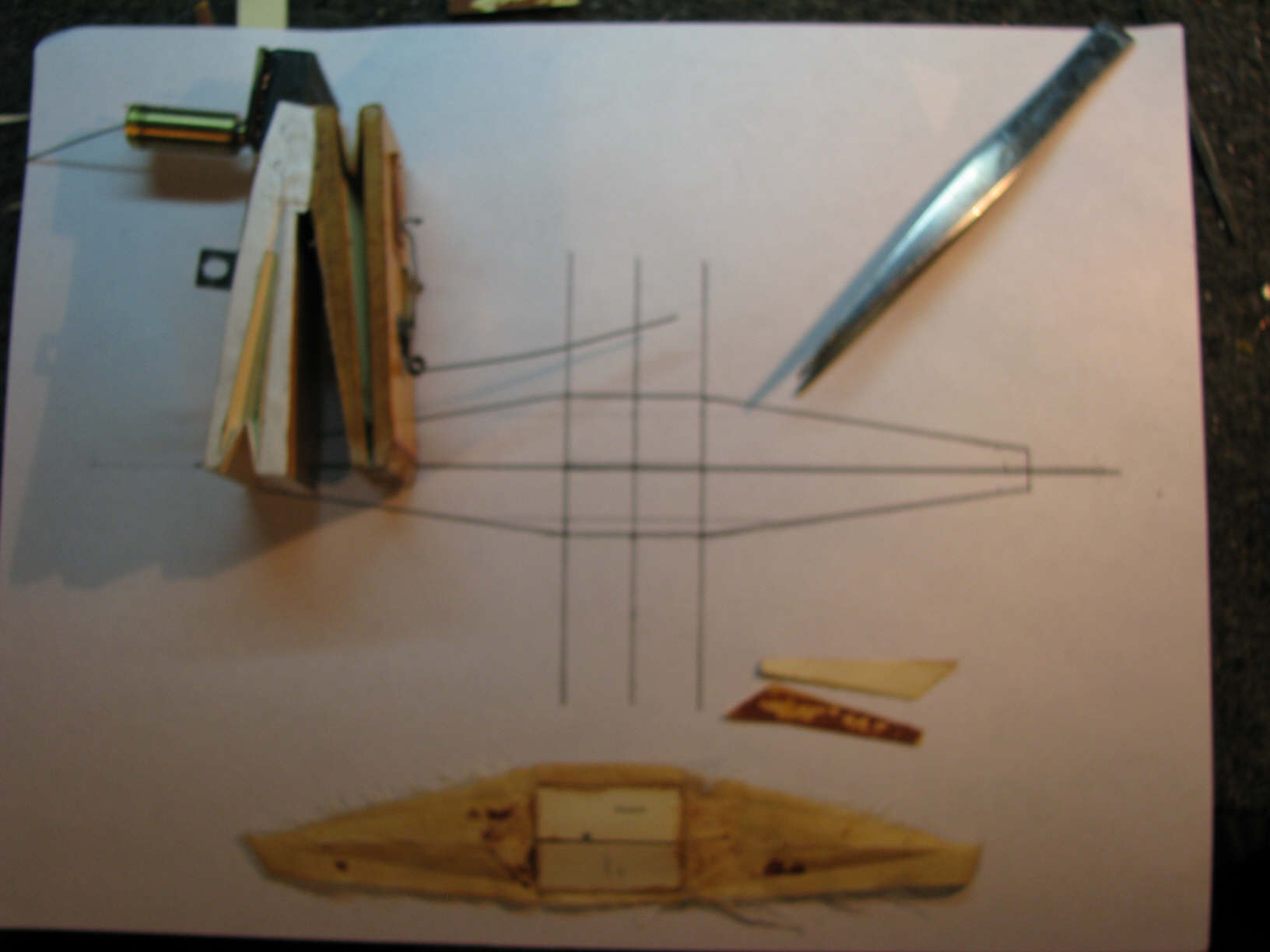

Turned out besides the bellows repair, the main gear, a form of plastic

in this, had missing teeth,

This condition most likely caused because it was over wound. The

yellow bird is in poor

shape as well.

To repair this cage requires contacting the factory in Germany for

parts.

Ok.... lets get started.

On the left the damaged gear, then the

right the very sad looking yellow bird followed by the red bird ,

missing an eye

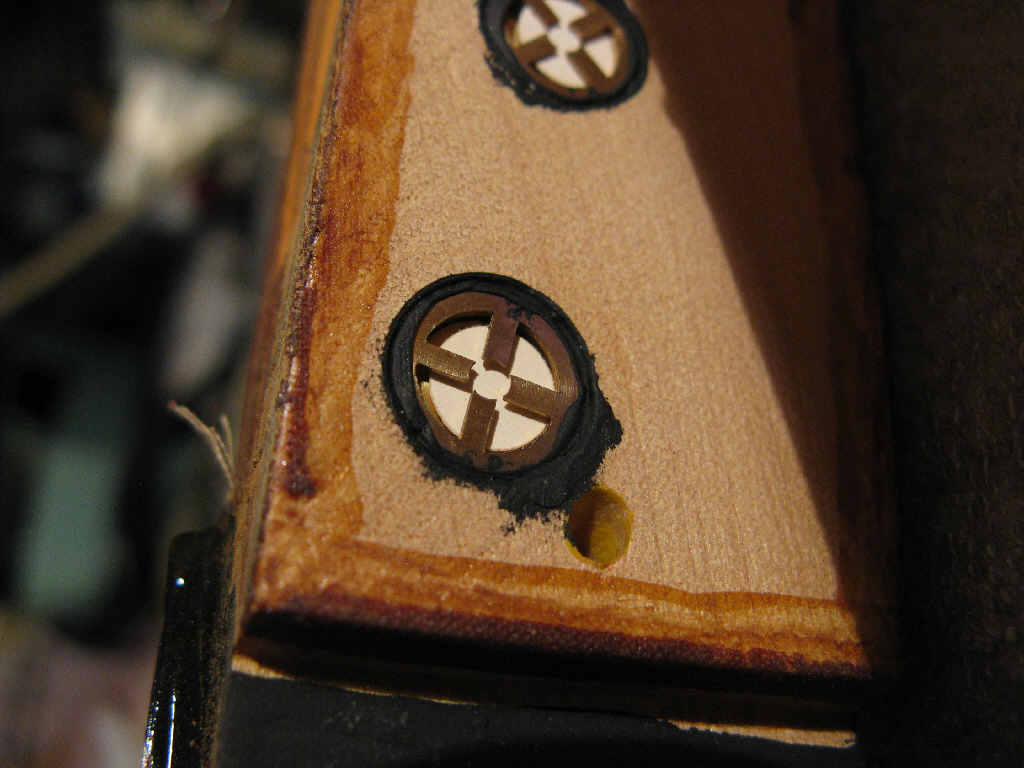

This shows the later valves used in

the bellows.

That is a brand new yellow bird on the

right straight from the factory

in Germany.

The platform restored, new gear

installed, new yellow bird synced to

mechanism (movement), new eyes, base polished and repaired, and of

course

bellows serviced and whistler

adjusted. I think all the work and

expense was worth it, as you can see for yourself.

Finished !

For those out there reading this, it

has be brought to my attention that there are "fakes" of these being

sold

So, at this stage I'm not sure how you can differentiate between

real and fake at this point, but buyer beware.

Some sellers may not be aware they are selling a chinese copy.